Die Stamping - Cloisonne - Hard Enameling

The production method for manufacturing coloured cloisonne or hard enamel lapel pin badges is die

stamping. The techiniques used for custom logo cufflinks is very similar, in the fact both products would be die

struck with your logos profile including all raised / recessed surface detail. The only difference

for enamel pins is we would add an outline to your logo to form an outer edge for the enamel to be

encased. All enamel badges and cufflinks would then be baked then left to set hard, ground down,

buffed ready to polish then gold or silver plated to suit.

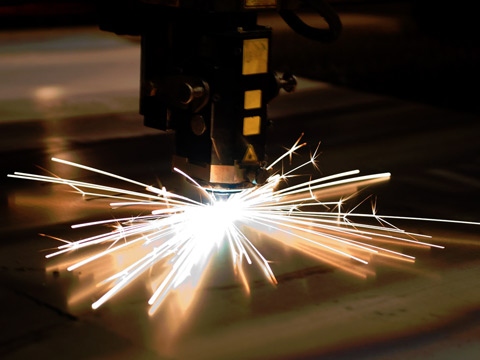

Laser Cutting - Engraving

The production techniques used to manufacturer some logo designs are Laser cutting, (also known as laser

profiling) and Laser Engraving. These production processes are incredibly flexible. We can cut and

engrave virtually any logo design in a variety of flat metal, wood and acrylic sheet materials.

High powered Industrial Lasers are used to cut different materials, and specialist lasers for the

engraving. Digital tooling enables low cost, rapid turnaround of prototypes and mass production.

Design modifications are accommodated quickly and inexpensively. Tool set up fees range from £150

for laser cut metal designs, (if your order is more than £150 the set up fee is discounted to £100.) Our

customers CAD / design data is imported to allow cut simulation and sheet layout optimisation,

ensuring we have a quick response to enquiries.

Design Considerations

A hole cut with a laser has an entry diameter minimally larger than the exit diameter, creating a

slightly tapered hole. The minimum internal radius for slot corners is 0.2mm. Unlike stamping, the

normal design rules regarding minimum wall thickness, minimum hole size (as a percentage of material

thickness) does not apply.

The minimum hole sizes can be as low as 20% of material thickness, with a minimum of 0.25mm for up to 1.9mm material. Burrs are virtually eliminated and are insignificant when compared to those produced by shearing or blanking.

Photo Etching

Etching is used for bulk quantity orders where your design requires intricate surface details. If

your logo is more than 1.5mm thick your surface etched design will need to be laser cut after the

etching process. If your logo is made from 1.5mm thick metal and below we can surface etch details

and etch all the way through the parts of the metal you don't want to keep. The maximum depth of

surface etch we can achieve is 0.3mm, this is why etching is not suitable for hard enamel pin badges

or cufflinks as the enamel needs to have a deeper recess that you can do with die stamping. Etching

is best suited to stainless steel and quicker manufacturing lead times, resulting in more cost

effective unit costs.

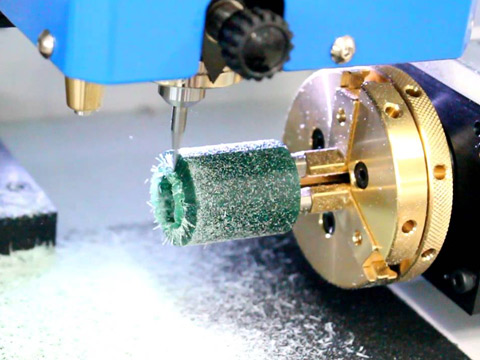

Precious, Non Precious Metal Lost Wax Casting

We commonly use traditional jewellery casting techniques to produce more complex logos from silver

and gold. In most cases we will hand make a master proto type of your logo then make a rubber mould

for reproduction, if you had an object than you would want us to replicate then we could use a cold

rubber mould to eliminate any potencial damge to your item. Your logo is then lost wax cast into

your desired metal alloy. A one off mould charge of £25 applies.

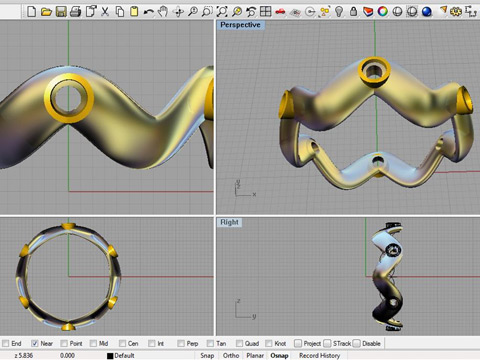

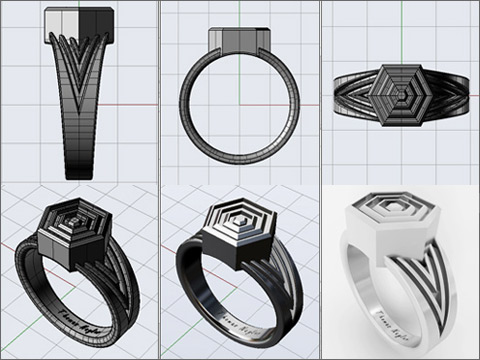

CAD Modelling Design - Rapid Prototyping

Another popular more modern solution we offer our customers is Computer Aided Design (CAD) which has revolutionised the way we can design and manufacture jewellery. Here at Bespoke Logos we are avid fans of this modern manufacturing technique due to the fact you can achieve very complex, perfectly symmetrical and accurate 3D designs which would simply not be possible to hand make to the same high standard.

By using CAD software we are able to create advanced 3D jewellery models which can incorporate your company logo if required. From your idea or sketch we can produce a Bespoke 3D CAD model to your exact specifications. For all precious jewellery commissions a photo realistic rendered image will be emailed to you for approval and changes made as required. Once the design has been finalised we will rapid prototype (using a 3D printer) the CAD model from wax ready for lost wax casting directly into your desired metal alloy.

Once your jewellery design has been cast Thomas Nayler skilfully hand finishes every piece and sets the gem stones to perfection. With almost 20 years in the jewellery industry and being Hatton Garden trained you are guaranteed a quality personal product to show off or market your branded products in style.

Finished Components from One Source

Combining Laser Cutting/Etching/Casting/Rapid Prototyping with other in-house traditional

jewellery manufacturing processes and finishing techniques means we can provide our customers

with finished high end logos that are quality checked at every stage enabling you to reduce your

supplier base and save valuable time, money on marketing. All of our high end logo jewellery is

made in the UK, large orders of cheaper products may be outsourced to our reliable trade

contacts that we have build up trust with over the years to offer you peace of mind.

If you would like further information on which manufacturing technique is best suited to produce your design please contact us.

Back To Top

All Work ©opyright Thomas Nayler Ltd & BespokeLogos.co.uk 2003 - 2023. All Rights Reserved | Company Number: 11897500 | VAT Reg: 136568686 | Protected by A©ID